One often overlooked tool to reduce costs is to build in optimum lot sizes or the Economical Build Quantity (EBQ). Of course, you should diligently try to minimize set-up costs, aim for single piece flow etc., but with many planes being built in quantities of one plane a month (or less), there will never be enough volume to justify the expense necessary to reduce setups to zero. Producing in correctly-sized lots will be the most economical option.

What is your Economical Build Quantity?

Well, you can try to guess it, but that can cause your costs to be larger than necessary. Sometimes much larger.

Building in lot sizes that are too large minimizes set-up but increases “holding” costs by having parts in inventory. These inventory costs are very visible so they generate a well-justified effort to reduce them. Building in lot sizes that are too small increases overhead costs but in a way that is much harder to track, find, and reduce.

To calculate your Economical Build Quantity, you need four numbers:

- Recurring costs: any cost that goes up in direct proportion to the number of parts produced, mostly material cost and per-piece labor costs.

- Non-recurring costs: Any cost you can divide by the number of parts produced

- Cost of money: Either what your bank charges or opportunity cost, your choice

- Usage rate: The forecast rate of usage

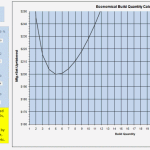

The EBQ Calculator

Aero-Spaces has developed a software tool that graphs the results of the quantity built vs. cost each to build—the EBQ curve. That way, you can discover the perfect quantity to manufacture, and what it would cost to build more or less. It’s very simple to play around with numbers using intuitive sliders, giving you instant results to see what would take some number crunchers hours to recreate.

Perhaps you are willing to pay an extra few percent in manufacturing costs to build four parts rather than the optimum of six, because you suspect the usage rate may decrease. Conversely, you may decide to pay an extra few percent to have a small safety stock in a time when you anticipate, say, a machine being down for maintenance. With the EBQ curve, you can base your lot size decisions on hard information, perhaps saving several percentage points of cost, which goes directly to the bottom line. With the current squeeze of profits, a few percentage points can make a big difference.